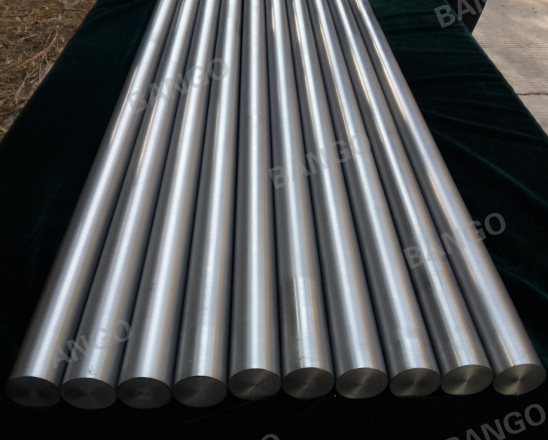

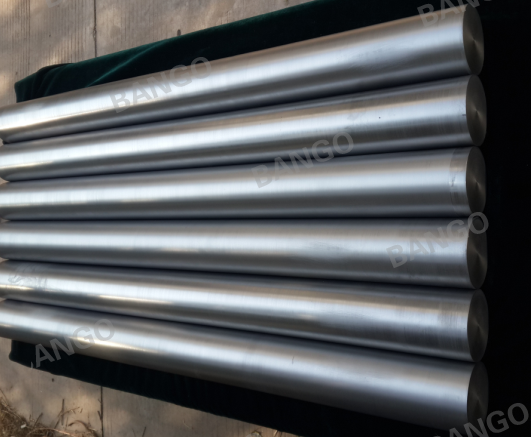

Molybdenum rod introduction

| Appearance | silver grey metal luster |

| Purity | Mo≥99.95% |

| Density | not less than 10.2g/cm3 |

| Supply state | annealing or processing |

| Quality standards | GB/T 17992-1999, GB/T 4188-1984 ,ASTM B387-90 |

Unit: mm

| Width | Length | Surface | State | Diameter/height | ||

| bar | 14 | 400 | bright | sinter | 14 | |

| rod | — | 10~400 | bright | sinter | 200~400 | |

| — | 10~900 | black | forged | 100~200 | ||

| — | 10~1200 | black | forged | 20~100 |

Special sizes can be manufactured based on customers' requirements

| Production process | Materials -- CIP -- IF induction sintering -- forging—annealing -- mechanical processing -- Molybdenum rod |

| Production equipments | Cool isostatic pressing machine(CIP), IF induction sintering furnace, forging machine, coreless grinder ,CNC vertical turning machine, wire cutting machine |

| Application | Since the density is 10.2 g/cm3,and the melting point has reached 2640oC, Molybdenum rods with high temperature resistance and high creep resistance often used in high-temperature furnace, vacuum furnace, and sapphire crystal furnace. Molybdenum added rare earth or TZM added Titanium, Zirconium, C elements has a higher recrystallization temperature and better high temperature creep resistance, it is widely used in aerospace, military weapons, etc. |

Bango can provide molybdenum bars and rods that made with molybdenum powder which purity is 99.95%. After sintering and forging, the density of molybdenum rod basically comes close to molybdenum’s theory density, so they have a good high-temperature strength and electrochemical corrosion resistance.

Next :Molybdenum Wire

Prev :Molybdenum Sheet