| Grade | W1, W2, W3, W4 |

| Width * Length | (2.0-500.0mm)*(2.0-500.0mm) |

| Thickness | 0.2mm-15.0mm |

| Density | Purity 99.92%, 99.98% can also be achieved if special demanded. |

| Surface | Sintering surface, Forged surface, Ground surface |

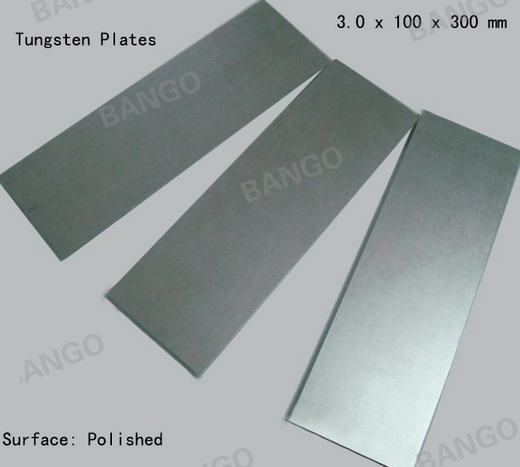

Tungsten sheet and plates are produced from billets by special cold and hot rolling technology. Plates can be used to make: electrodes, heat elements, heat shield, Boats for electronics, lightning, and electro vacuum industries.

| Thickness | Thickness tolerance | Width tolerance | Length tolerance | Type | Process | Delivery condition | Size (mm) | |||

| Grade I | Grade II | Thickness | Width | Length | ||||||

| 0.10-0.20 | ±0.02 | ±0.03 | ±3 | ±3 | W1,2,3,4 | P/M | Cold rolled (Y)Stress relief annealing (m) | 0.10-0.20 | 30-250 | 50-500 |

| >0.20-0.30 | ±0.03 | ±0.04 | ±3 | ±3 | ||||||

| >0.30-0.40 | ±0.04 | ±0.05 | ±3 | ±3 | >0.20-0.4 | 50-250 | 50-500 | |||

| >0.40-0.60 | ±0.05 | ±0.07 | ±4 | ±4 | ||||||

| >0.60-0.80 | ±0.07 | ±0.08 | ±4 | ±4 | ||||||

| >0.80-1.0 | ±0.08 | ±0.12 | ±4 | ±4 | Hot rolled (R)Stress relief annealing (m) | >0.40-4.0 | 50-200 | 50-200 | ||

| >1.0-2.0 | ±0.12 | ±0.20 | ±5 | ±5 | ||||||

| >2.0-3.0 | ±0.20 | ±0.30 | ±5 | ±5 | >4.0-6.0 | 50-200 | 50-200 | |||

| >3.0-4.0 | ±0.30 | ±0.40 | ±5 | ±5 | ||||||

| >4.0-6.0 | ±0.40 | ±0.50 | ±5 | ±5 | ||||||

| Production process | Materials---hot rolling---annealing---cold rolling---leveling---annealing---machining---tungsten sheet |

| Production equipments | four-high cold mill, vacuum annealing furnace, W43G series straightener, hydraulic plate shears, water jet, wire cutting machine, flat-stone mill |

| Appication | Since the melting point of tungsten has reached 3380oC, tungsten sheet is widely used in reflection shield, cover plate applied in the sapphire growth furnace, reflection shield, heating tape, connecting pieces applied in vacuum furnace, sputtering target applied in plasma coating film, and high temperature resistance boat. |

| Quality stansard | GB/T 3875-2006 (tungsten plate) |

Next :Tungsten Boats

Prev :Tungsten Wire